How do these corrosion inhibitors work?

The VCI active ingredient changes into a gas phase in the packaging and thus wets the packaged metal parts. The metal parts are completely protected by the gaseous active ingredient, even in the smallest holes.

The VCI films from Horn & Bauer work with both ferrous and non-ferrous metals.

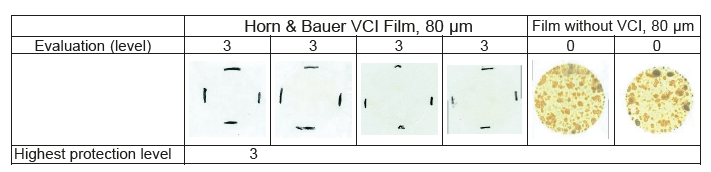

Our VCI films achieve excellent protection

- Proven by the Institut für Lacke und Farben Magdeburg GmbH

- Top marks in comparison with products from other manufacturers

Premium quality directly from the manufacturer

- Over 20 years of experience in the production of VCI films

- Horn & Bauer is an approved supplier in the automotive industry and the automotive supply industry

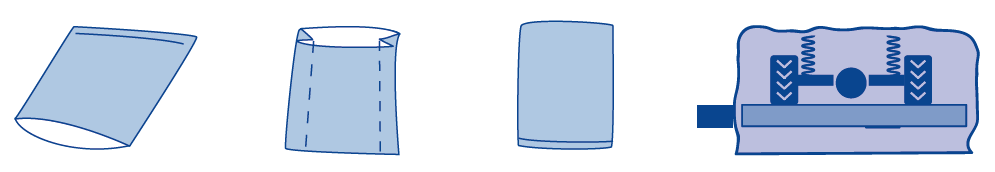

Films – Delivery forms

-

Extrusion

- Flat films from 200 mm to 2,300 mm

- Half-hose from 100 mm to 2,300 mm (unfolded up to 4,600 mm)

- Hose from 200 mm to 2.300 mm

- Side gusset from 200/100 to 1,500/1,100 mm (unfolded up to 5,200 mm)

- Film thickness from 0,060 mm to 0,150 mm

-

Ready-made delivery forms

- Bags, sacks, hoods

• Widths from 100 – 2.000 mm

• Lengths from 100 – 10.000 mm

- Bags, sacks, hoods

-

- Side gusseted bags

• Widths from 100 – 2.000 mm

• Depths from 1000 – 3.000 mm

- Side gusseted bags

Compliance with safety rules

The safety instructions TRGS 615 and TRGS 552 apply to the production and use of corrosion protection agents for the temporary protection of metal objects.

Of course, the VCI films from Horn & Bauer comply with these technical rules.